Production Streets

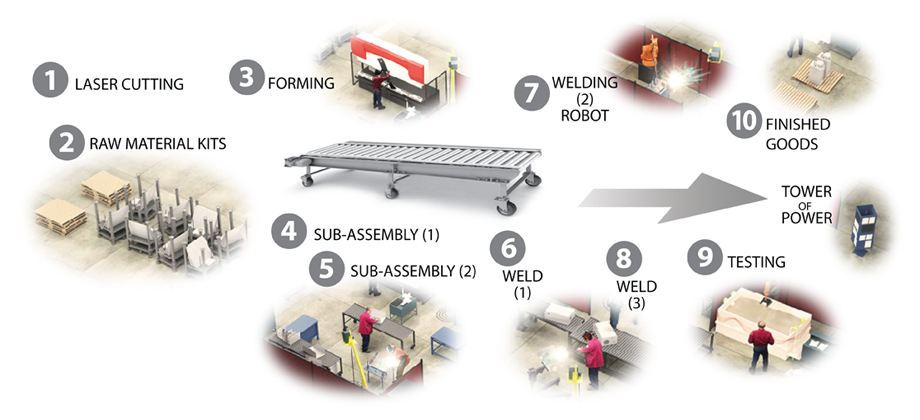

Helgesen Streets — are linear work cells where single products are built sequentially, one piece at a time, from raw materials thru completion. Each street team builds a product following a standardized work flow – with parts added in linear sequence. All value-added production tasks for each part are contained within the Street. This concept allows for the least-cost method of manufacturing hydraulic tanks with minimized work-in-process. The diagram below shows one typical layout of a Helgesen Production Street.

Standardized work allows Helgesen to add and share essential quality controls between team members. The focus is on productivity, quality, cost objectives and delivery.

The Helgesen R4 Production System optimizes the manufacturing of products to each customer’s demands by integrating processes and resources in a continuous linear flow path. The flow path (or production street) incorporates dedicated teams that link dissimilar work centers to maximize delivery, productivity and quality performance.

Street Teams consist of 3-9 people and one Street Captain. Each Street Team integrates process verification through buddy checks, supported by AWS certified welders and complex metrology (as required).

Street Captains work side-by-side with their Street Team Members. The captain is also responsible for performing Street Audits, validating that processes are executed correctly.