Hydraulic Reservoir System Design

Through extensive hydraulic fluid analysis, Helgesen has developed multiple patented technologies to meet increasing market demand in hydraulic efficiency and performance, becoming the global leader in hydraulic fluid conditioning technology.

- Reduction in Tank Cost

- Improved Oil Life

- Enhanced Filtration

- Reduction of Tank Size up to 90%

- Improved Hydraulic Efficiency

- Remote Filter Placement

- Reduction of Hydraulic Fluid

- Rapid De-aeration

Configurable

Configurable

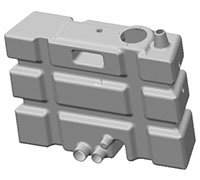

140 Gallon

35 Gallon Non-Metallic

Nylon 6, polypropolene, aluminum, stainless, and carbon steel

Disruptive air removal technology utilizing complete system fluid management

State of the art surface treatment Cleanliness

Proprietary technology to reduce splash volume percent (SVP) and turbulence kinetic energy (TKE) of fluid

Increased utilization of available fluid

Product Validation and Testing

Capabilities to validate design and quantitatively analyze hydraulic fluid properties and performance:

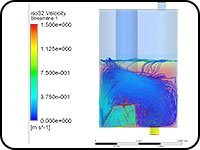

- CFD Simulation

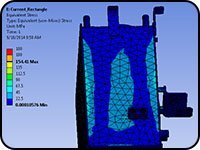

- FEA Simulation

- Lab Simulation – multi-pump, variable flow rates, cylinder extension, variable grade

- On Machine Testing – fluid condition, pressure, temperature, flow rate

Real time data acquisition for hydraulic testing

Computation fluid dynamics (CFD) to predict turbulence, sloshing and fluid path

Slope simulation testing system

Complex structural engineering analysis utilizing finite element analysis (FEA)