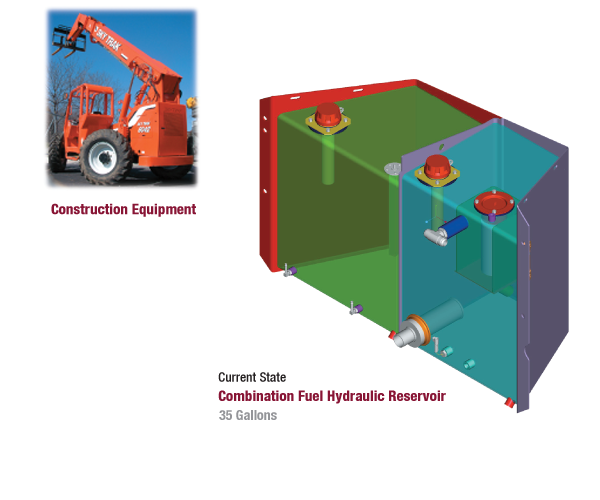

Combination Fuel and Hydraulic Reservoir

Challenge

A large OEM of telescopic material handling equipment had experienced severe quality defects on its combination fuel/hydraulic reservoir causing assembly line downtime and field warranty failures.

Solution

Utilizing the Helical Program, Helgesen helped the customer realize a cost savings of 9% while producing a defect-free assembly utilizing the following techniques:

- Reduced potential failure modes by redesigning the reservoir. Modified part fit-up, bend radii, material types and drain locations to create a defect-free assembly.

- 50% reduction in reservoir leak point weld seams.

- 7x increase in manufacturing throughput by applying R4 production streets.

- In-house paint capabilities enabled better appearance control for a highly cosmetic assembly.